Industrial cooling system are a critical component used in industrial facilities to improve product quality. These systems are designed to optimize temperature conditions in a wide range of sectors including food, chemical, pharmaceutical, metal, and more.

Industrial cooling system also play a significant role in reducing energy consumption and achieving environmental compliance goals for businesses. With advancing technology, more efficient and eco-friendly cooling solutions are being developed, helping businesses achieve their sustainability goals.

The most common sectors where industrial refrigeration systems are extensively used include:

- Food and Beverage Industry

- Chemical and Pharmaceutical Industry

- Plastic and Rubber Industry

- Metal Processing and Casting

- Energy Production

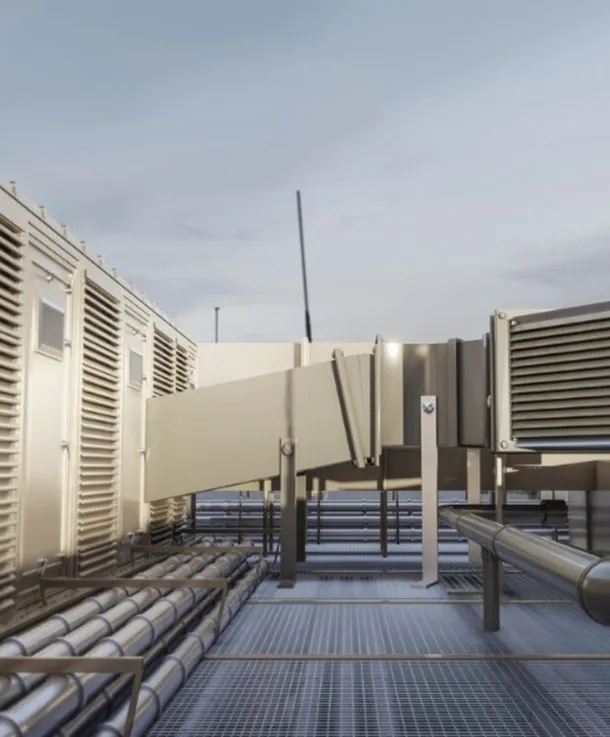

Industrial Type Cooling Systems

Industrial type cooling systems are indispensable elements of modern industry and have a wide range of applications. These systems are critical for increasing the efficiency of production processes, preserving product quality, and optimizing energy consumption.

Industrial refrigeration systems are designed with the needs of businesses in mind. These systems can be customized to meet specific industrial needs and can be developed using various cooling capacities and technologies. To increase energy efficiency and reduce operational costs, cooling systems may utilize renewable energy sources or integrate waste heat recovery systems.

Ventilation systems are an important component of industrial cooling systems. Effective ventilation not only improves indoor air quality but also maintains humidity and temperature balance. This not only increases the efficiency of cooling systems but also makes the working environment healthier and more comfortable.

The use of cold storage equipped with cooling and ventilation systems is particularly important for storing and preserving sensitive products such as food and pharmaceuticals. These storages ensure that products are kept without spoilage, maintaining their freshness and quality over a long period.

How Industrial Cooling Systems Work

Cooling water is one of the basic components of these systems and facilitates heat transfer in the cooling cycle, enabling the systems to work effectively. Industrial cooling applications are designed to meet specialized cooling needs, ranging from heavy industry to light industrial operations.

Compression cooling systems consist of a compressor, condenser, expansion valve, and evaporator. The working principle of these systems is based on the cyclical compression, condensation, expansion, and vaporization of a refrigerant fluid.

Absorption cooling systems operate using heat energy and typically utilize heat sources such as natural gas or steam. These systems employ a refrigerant fluid and an absorbent material. The refrigerant fluid, when heated, vaporizes and then dissolves in the absorbent material. Later, a heat source warms this solution, vaporizing the refrigerant fluid again. This vapor, once condensed, absorbs heat, thus performing the cooling process.

Evaporative cooling utilizes the cooling effect of water evaporation. These systems work by spraying water over a pad or surface and directing air flow towards this water with a fan. As water evaporates, it lowers the air temperature, and the cooled air is directed to the desired area.

Maintenance and operation of industrial cooling systems are also crucial for ensuring their long lifespan and efficient performance. Regular maintenance and checks allow for the early detection and rectification of potential failures.

For information on industrial ventilation and cooling systems, you can contact AIRFAN.