Centrifugal pump is a type of pump used to move liquids. The rotational motion of the motor in the pump transfers energy to the liquid through blades, accelerating the liquid and moving it out of the pump. The speed gained by the liquid as it exits the pump is converted into pressure energy.

Centrifugal pump is used in many different areas such as water supply, wastewater treatment, the chemical industry, mining, agricultural irrigation, and fire extinguishing systems. These pumps generally consist of a body, an impeller, a shaft, and sealing elements. The body is the main part where the liquid is pumped. The impeller is the rotating part that moves the liquid. The shaft transfers power from the motor to the impeller.

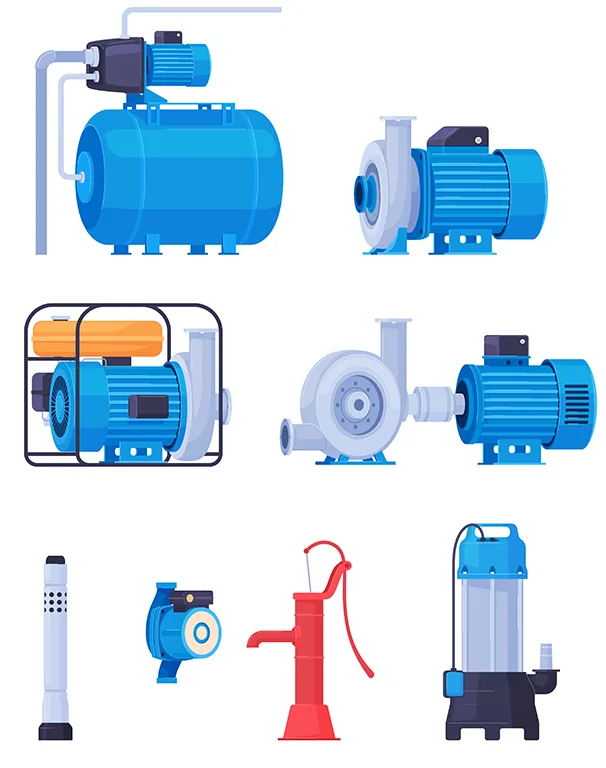

Centrifugal pumps are widely preferred in various industries and applications due to their versatile use. Some of the applications of these pumps are as follows;

These pumps are used in municipal water supply systems, water supply and pressurization systems of buildings. They distribute water from reservoirs or underground sources to buildings and facilities.

These pumps play a significant role in transporting dirty water and treated water. They are used to transport wastewater to treatment facilities and discharge it after treatment.

In agricultural irrigation, centrifugal type pumps can be used to distribute water from sources to fields and gardens. These pumps offer an effective and efficient solution for irrigating large areas.

Centrifugal type pumps are utilized in many sectors like the chemical, petrochemical, food processing, and mining industries. These pumps are used for transporting and processing various chemical and liquid materials.

Heating, ventilation, and cooling systems, fire extinguishing systems, and maritime are also common areas where these products are used.

What is a Centrifugal Pump?

These devices are a type of pump widely used in domestic and industrial applications. Utilizing rotary motion to move liquids, these pumps are preferred for their efficiency and reliability. So, what is a centrifugal type pump, and what are its advantages and disadvantages?

Advantages

- Centrifugal pumps can transport liquids with high efficiency. This reduces energy consumption and lowers operating costs.

- The structure of these pumps is relatively simple, which makes maintenance and repair easier. Also, due to fewer moving parts, the failure rates are low.

- Centrifugal pumps are available in different sizes and capacities, offering solutions suitable for various applications and needs.

- These pumps can be used in water supply, wastewater treatment, chemical processing, HVAC systems, and many other areas.

- Some centrifugal pump models have self-priming features, allowing them to draw liquids without needing an additional suction pump.

Disadvantages

- These pumps can be damaged when run dry. Therefore, it is necessary to keep them in constant contact with the liquid.

- As viscosity increases, the efficiency of these pumps decreases. Therefore, centrifugal model pumps are not suitable for transporting high-viscosity liquids.

- Cavitation can occur in the pump if there is insufficient feed pressure. This can damage the pump impeller and other components.

- The initial installation cost of some centrifugal pump systems can be high, especially for large-scale industrial applications.

- Liquids containing gas can reduce the efficiency of centrifugal pumps and, in some cases, prevent the pump from operating properly.

How does a centrifugal pump work?

The basic working principle of a centrifugal pump is the use of centrifugal force. The rotational movement of the motor is transferred to the rotating bladed section of the pump, known as the impeller. This rotation accelerates the liquid and propels it out of the pump. During this process, the kinetic energy of the liquid is converted into pressure energy, thereby elevating the liquid to the desired height or pressure.

Submersible centrifugal pumps are a type of pump completely submerged in water for operation. They are commonly used in deep well applications and for draining water-flooded areas. The biggest advantage of submersible pumps is their ability to work under water. This structure increases the efficiency of the pump under water pressure and allows achieving higher pressures.

Stainless steel centrifugal pumps are used in applications where resistance to corrosion is necessary. They are preferred in areas such as chemical processing, the food industry, and clean water applications. The stainless steel material ensures these pumps are long-lasting and durable. The working principle of stainless steel centrifugal pumps is the same as other centrifugal pumps. The quality of the material used allows these pumps to cope with more aggressive liquids.

AIRFAN is an experienced company manufacturing and selling many devices in this field. Contact us for ventilation systems and many other industrial products that suit your needs.

Centrifugal Pump Prices

Centrifugal pumps, which move liquids with high-speed rotating impellers and are generally used in industrial, agricultural, or domestic areas, have prices that vary based on several factors. These pumps have a wide range of applications, and their features impact the pricing.

Another criterion that affects the prices is the area in which the pump will be used. For example, tractor centrifugal pump prices used in agriculture differ from those used in industrial settings.

The main factors affecting prices are as follows:

- In terms of pump quality and flow capacity, centrifugal pumps have different pressure and flow capacities. High-flow pumps can transport water faster and over longer distances. These are generally preferred in industrial areas, and their prices are higher.

- The material used in the pump has a significant effect on the price. For example, materials like stainless steel, cast iron, and bronze enhance the durability of the pumps, thus increasing the price.

- Another factor influencing prices is the power of the motor. More powerful motors have higher energy capacities, which directly impacts the price. Large-scale water projects or industrial applications that require high pressure often require higher motor power.

- The brand and manufacturer can also lead to price differences. Local brands tend to be more affordable and offer quality options.

All these factors directly influence the prices, and paying attention to these details can ensure long-term benefits in usage.

Second-Hand Centrifugal Pumps

A popular option among centrifugal pumps is second-hand pumps, which are more affordable compared to new ones. However, there are certain points to consider when choosing second-hand pumps, as making the wrong choice can lead to higher costs in the long run. When choosing second-hand pumps, it is important to pay attention to the following:

Centrifugal pumps come in various types, and these differences also impact the prices.

Single-stage pumps are used for low-pressure, high-flow applications and are structurally less complex, making them more affordable. Multi-stage pumps, on the other hand, are ideal for applications requiring high pressure.

Horizontal pumps are more commonly used, while vertical pumps offer advantages such as space-saving and high pressure.

Closed impeller pumps provide higher efficiency and better performance. Open impeller pumps, on the other hand, are suitable for pumping liquids containing solid particles, such as in waste or dirty water systems.

Self-priming pumps are generally preferred in agriculture and irrigation applications.

Other types include 2.2 hp and 4 hp pumps, which stand out in terms of their power capacities. Pumps with 2.2 hp motor power are generally more affordable, while 4 hp pumps are designed for higher-capacity water pumping.

For large-scale applications, industrial pumps are used, made from durable materials. Other types include domestic and agricultural pumps, as well as magnetic drive centrifugal pumps