Centrifugal pump prices vary depending on many different factors. These factors include the capacity of the pump, material quality, technology used, brand and additional features.

Centrifugal pump prices vary depending on the size, type and manufacturer of the pump. In general, a small and simple pump for home use can be found at more affordable prices. However, large industrial-scale models with special features are more expensive.

Centrifugal Pump Prices 2024

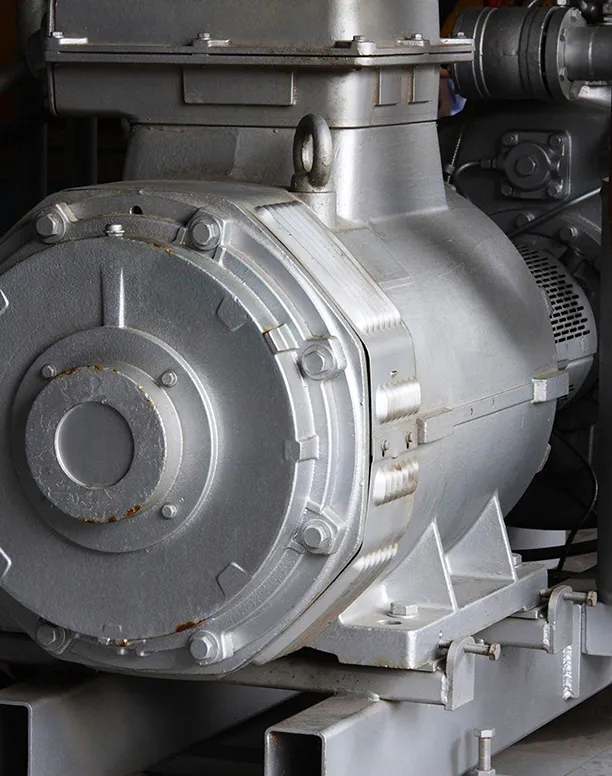

What is a centrifugal pump? A centrifugal pump is a mechanical device designed to move fluids by transferring rotational energy through one or more driven rotors known as impellers. This type of pump is widely used in various industries including water purification, chemical processing and irrigation due to its efficiency and versatility in handling different types of fluids.

Some of the factors that affect the prices of centrifugal pumps used in many areas such as water supply, wastewater management, irrigation aeration systems are as follows:

Capacity and Power: Flow capacity and pressure capacity of the pump expressed in liters/minute or cubic meters/hour.

Material: Use of different materials such as stainless steel, cast iron, plastic.

Brand and Manufacturer: Different manufacturers and brands in the market may differ in terms of quality and price.

Technology Used: Technological features such as energy efficiency, advanced control systems.

Application Area: Pumps customized for various areas of use such as domestic, agricultural, industrial.

After Sales Services: Services such as warranty period, technical support, spare parts supply.

3 Stage Centrifugal Pump Prices

3-stage centrifuges are complex machines used to separate solid particles from liquids and are commonly used in industrial processes. Prices of 3-stage centrifugal pumps are generally higher than single-stage centrifugal pumps. This price difference is based on several factors:

3-stage centrifugal pumps have multiple impellers and a more complex internal structure supporting these impellers. Each extra stage impeller increases the material and production costs of the pump.

The additional materials and more complex manufacturing processes required by having more than one stage increase the cost of 3-stage pumps. Material quality and durability is also a factor, as these pumps are generally designed to withstand higher pressure levels.

3-stage pumps have the capacity to deliver higher pressure and efficiency. This superior performance may be required for more demanding applications such as water supply of high-rise buildings, water extraction from deep wells and industrial processes. The ability to offer a high performance solution is another important factor that increases the price of these pumps.

These pumps are often designed for more specific and demanding applications. These specific application requirements may require the pumps to be more costly.

To get up-to-date and specific price information, it is best to visit the websites of manufacturers or authorized dealers directly, browse product catalogs or contact sales representatives. In this way, you can evaluate the most suitable centrifugal pump options for your needs and budget.